Views: 0 Author: Site Editor Publish Time: 2025-10-02 Origin: Site

Expanded metal mesh is a versatile material used in construction and industrial applications. However, rust can compromise its integrity. Preventing rust on metal structures is crucial to maintaining durability and safety. In this post, you'll learn about effective rust prevention methods, including using stainless steel wire and advanced techniques like galvanizing and VCI packaging.

Rust forms when iron or steel reacts with oxygen and moisture in the environment. This chemical reaction produces iron oxide, commonly known as rust. The process begins when moisture, such as water or humidity, comes into contact with the metal surface. Oxygen from the air then reacts with the iron atoms in the metal, creating a flaky, reddish-brown layer. This layer is porous and does not protect the metal underneath, allowing rust to spread and weaken the structure over time.

Rust significantly compromises metal's strength and durability. As rust spreads, it eats away at the metal, causing it to become brittle and flaky. This deterioration can lead to structural failures, safety hazards, and costly repairs or replacements. Rust also affects the appearance of metal, making it unsightly and less desirable for architectural or decorative uses. In industrial settings, rust can impair machinery functionality, leading to downtime and increased maintenance costs.

Rust is a specific type of corrosion that occurs only on iron and its alloys, like steel. Corrosion is a broader term describing the gradual destruction of any metal due to chemical reactions with its environment. While rust results from iron oxidizing in the presence of water and oxygen, corrosion can happen to other metals through different chemical processes. For example, aluminum forms a protective oxide layer that prevents further corrosion, whereas copper develops a green patina. Understanding this distinction is crucial for selecting appropriate prevention methods for different metals.

Stainless steel is a top choice when preventing rust on expanded metal mesh. Its key advantage lies in its composition—mainly iron combined with at least 10.5% chromium. This chromium forms a thin, invisible protective layer called chromium oxide on the metal’s surface. This layer acts like a shield, stopping oxygen and moisture from reaching the iron beneath. Because rust forms when iron reacts with oxygen and water, this barrier greatly slows or even stops rust from forming.

Another benefit is the self-healing property of this chromium oxide layer. If scratched or damaged, the layer can repair itself as long as oxygen is present. This means stainless steel can maintain its rust resistance even after minor surface damage, making it ideal for outdoor or harsh environments.

Moreover, stainless steel is durable and strong, which suits expanded metal mesh used in industrial, architectural, and security applications. It withstands wear and tear better than many other metals, reducing maintenance and replacement costs.

Stainless steel wire used in expanded metal mesh has several important properties:

● Corrosion Resistance: High chromium content prevents rust and other corrosion types.

● Strength and Flexibility: It can be stretched and formed into various mesh patterns without breaking.

● Aesthetic Appeal: It maintains a clean, shiny look over time, even outdoors.

● Heat and Chemical Resistance: It resists damage from high temperatures and many chemicals.

● Low Maintenance: Requires little upkeep compared to regular steel.

These properties make stainless steel wire a reliable material for expanded metal mesh that needs to last long without rusting.

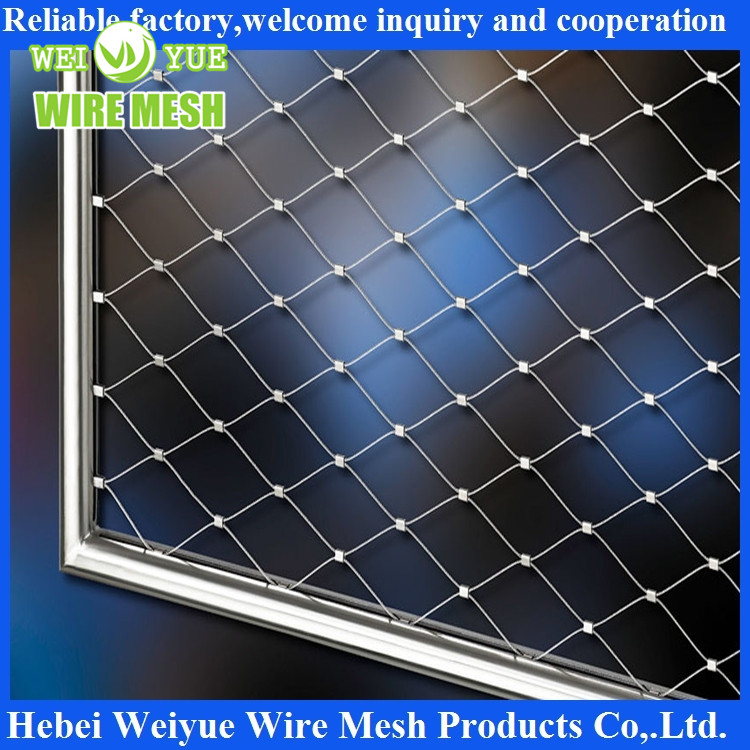

Stainless steel expanded metal mesh is used widely due to its rust resistance and strength. Common applications include:

● Industrial Use: Walkways, machine guards, and ventilation screens.

● Architectural Elements: Facades, sunshades, and decorative panels.

● Security: Fences, gates, and protective grilles.

● Automotive: Car grilles, heat shields, and filters.

In all these cases, stainless steel's ability to resist rust ensures the mesh remains functional and attractive over time, even in challenging environments like coastal areas or factories.

One of the most effective ways to prevent rust on expanded metal mesh is by using alloys designed for corrosion resistance. Stainless steel is a popular alloy choice because it contains chromium, which forms a protective oxide layer on the metal’s surface. This layer blocks moisture and oxygen, stopping rust before it starts. Other alloys, like COR-TEN steel, develop a stable rust layer that protects the metal underneath, slowing further corrosion. Selecting the right alloy depends on your environment and application, as some alloys perform better in harsh or salty conditions. Remember, alloys not only prevent rust but also enhance strength and durability.

Another common preventative method involves applying oil or dry coatings to the metal surface. Oil creates a thin barrier that keeps moisture away from the metal, effectively slowing rust formation. This method works well for tools or machinery parts but may cause slippery surfaces or attract dirt. For a cleaner alternative, dry coatings offer similar protection without leaving oily residue. These coatings form a thin, invisible film that blocks moisture and contaminants. They are easy to apply by spraying or dipping and are great for parts in storage, transit, or use. Combining dry coatings with other methods, like painting, can boost protection levels.

Painting expanded metal mesh provides a physical barrier to moisture and oxygen. Using oil-based paints is key since they adhere well and resist water better than water-based paints. Proper surface preparation, such as cleaning and priming, ensures the paint sticks and lasts longer. Keep in mind that any scratches or chips in the paint can expose the metal and start rusting. Powder coating is an advanced technique where powdered paint is electrostatically applied and then cured under heat. This process creates a thick, uniform layer that is tough and resistant to chipping, cracking, and corrosion. Powder coating is ideal for industrial or outdoor applications where durability matters.

Proper storage is crucial to stop expanded metal from rusting. Moisture is the main enemy since it triggers rust formation. To protect metal mesh, store it in a dry, well-ventilated space away from rain or water leaks. Avoid direct contact with the ground, which can hold moisture and speed corrosion. Instead, use pallets or racks to keep metal elevated.

Temperature control also matters. Sudden temperature changes cause condensation, which deposits water on metal surfaces. Keeping storage areas at a stable temperature reduces this risk. Ideally, store expanded metal in an indoor environment where humidity and temperature stay consistent.

In cases where moisture control is challenging, desiccants can help. These are substances like silica gel or clay that absorb moisture from the air. Placing desiccant packets near stored metal items reduces humidity around them, lowering rust risk.

For high-value or sensitive expanded metal products, controlled environments such as climate-controlled rooms or sealed containers with humidity control systems offer superior protection. These environments maintain low humidity, stable temperature, and clean air, all factors that slow or prevent rust.

Humidity plays a significant role in rust development. When relative humidity exceeds about 60%, water molecules cling to metal surfaces, enabling oxygen to react with iron and form rust. The higher the humidity, the faster rust forms.

Temperature influences this process too. Warm, moist air accelerates rusting more than cold, dry air. Conversely, very low temperatures slow chemical reactions, reducing rust speed. However, freezing and thawing cycles can cause moisture buildup, which is harmful.

In summary, controlling humidity and temperature in storage areas is vital for rust prevention. Keeping humidity low and temperature stable minimizes moisture on expanded metal, preserving its integrity and appearance.

Galvanizing is a popular rust prevention method that coats iron or steel with a thin layer of zinc. Zinc acts as a sacrificial metal, meaning it corrodes instead of the underlying metal. Since zinc corrodes much slower than iron, it protects the metal for a long time. The zinc layer also forms a barrier that blocks moisture and oxygen from reaching the steel surface, preventing rust formation.

There are two common galvanizing methods:

● Hot-dip galvanizing: The metal is dipped into molten zinc, creating a thick, durable coating.

● Electro-galvanizing: Zinc is applied using an electric current, producing a thinner, more uniform layer.

Hot-dip galvanizing is ideal for outdoor or industrial applications where strong protection is needed. Electro-galvanizing works well for decorative or indoor uses.

Despite its benefits, galvanizing isn’t perfect. Harsh environments like salty air or acid rain can wear down the zinc coating over time. Scratches or damage to the coating can expose the metal beneath, leading to rust. Still, galvanizing remains a cost-effective way to extend metal life.

Blueing is a traditional technique that protects steel by creating a layer of magnetite (Fe3O4), a black oxide, on the surface. This oxide layer is less porous and more stable than rust, so it slows corrosion.

The blueing process typically involves:

● Cleaning the metal thoroughly.

● Immersing it in a heated salt solution or applying chemicals.

● Heating to form the magnetite layer, which gives the steel a characteristic blue-black color.

Blueing is commonly used for firearms and precision tools. It provides moderate rust resistance but requires regular oiling to maintain protection. Without oil, the blueing layer can degrade, allowing rust to form.

Blueing does not offer as robust protection as galvanizing but is valued for its aesthetic appeal and moderate corrosion resistance.

Feature | Galvanizing | Blueing |

Protection Level | High, especially with hot-dip | Moderate, requires oil maintenance |

Appearance | Silver-gray zinc coating | Blue-black finish |

Durability | Long-lasting, resistant to scratches | Less durable, sensitive to wear |

Application Areas | Outdoor structures, industrial parts | Firearms, decorative tools |

Maintenance | Low, occasional inspection needed | Regular oiling required |

Cost | Generally affordable | Usually lower cost |

Overall, galvanizing provides stronger and longer-lasting rust protection for expanded metal mesh. Blueing suits applications where moderate protection and appearance matter, but it demands more upkeep.

Tip: For maximum rust prevention, choose galvanizing for heavy-duty outdoor expanded metal and consider blueing only when aesthetics and moderate protection are priorities paired with regular maintenance.

VCI packaging stands for Vapor Corrosion Inhibitor packaging. It’s a modern, chemical-based solution designed to protect metal surfaces from rust and corrosion during storage and transport. VCI technology involves infusing packaging materials—such as plastic films, papers, emitters, or foams—with special corrosion-inhibiting chemicals. These chemicals release vapor molecules inside the sealed packaging environment. The vapor molecules then settle on the metal surface, creating a thin, invisible protective layer that blocks moisture and oxygen, which are the main causes of rust.

Unlike traditional rust prevention methods that rely on oils or coatings, VCI packaging offers a clean, dry, and residue-free alternative. It’s especially useful for protecting expanded metal mesh and other metal parts during shipping or storage when exposure to moisture or contaminants is likely.

VCI packaging prevents rust by creating a controlled micro-environment around the metal. When the metal is enclosed in VCI-treated packaging, the vapor phase inhibitors saturate the airspace inside. These vapor molecules migrate and adsorb onto the metal surface, forming a molecular shield. This shield displaces moisture and oxygen, which are necessary for rust to form. The result is a corrosion-inhibiting film that protects even hard-to-reach areas, such as crevices and joints in expanded metal mesh.

Moreover, VCI molecules continually replenish themselves as long as the packaging remains sealed, providing long-term protection. This method avoids the mess and maintenance issues of oils or paints, making it ideal for parts that must remain clean or ready for immediate use.

VCI packaging is widely used in industries that handle metal components, including automotive, aerospace, electronics, and manufacturing. It’s particularly beneficial for expanded metal mesh products that require rust protection but cannot be coated with oils or paints due to functional or aesthetic reasons.

Key benefits include:

● Clean Protection: Leaves no oily residue, reducing cleaning or reprocessing needs.

● Comprehensive Coverage: Protects complex shapes and hidden areas.

● Long-lasting: Provides corrosion protection for months or even years if sealed properly.

● Cost-effective: Reduces damage, returns, and maintenance costs.

● Environmentally Friendly: Uses less hazardous chemicals compared to traditional rust inhibitors.

VCI packaging can be customized to different product sizes and types. For example, expanded metal sheets can be wrapped in VCI film or placed inside VCI-treated boxes or bags during shipping. This method ensures the metal arrives rust-free and ready for installation or further processing.

Expanded metal rust prevention involves using stainless steel, protective coatings, optimal storage, galvanizing, and VCI packaging. Selecting the right strategy depends on environmental conditions and specific applications. Future trends may include more sustainable and advanced corrosion inhibitors. Companies like Weiyue offer high-quality products with unique features that ensure durability and aesthetic appeal. Their expanded metal solutions provide long-lasting protection, reducing maintenance costs and enhancing product longevity.

A: Expanded Metal Mesh Stainless Steel Wire is a durable material made by stretching and cutting metal sheets, often using stainless steel wire, which resists rust due to its chromium content forming a protective oxide layer.

A: Prevent rust on Expanded Metal Mesh Stainless Steel Wire by using stainless steel with high chromium content, applying protective coatings like oil or powder, and storing it in dry, controlled environments.

A: Stainless steel wire for Expanded Metal Mesh offers superior rust resistance, durability, and aesthetic appeal, making it ideal for various applications like industrial, architectural, and security uses.