Views: 0 Author: Site Editor Publish Time: 2025-10-04 Origin: Site

Ever wondered how stainless steel wire transforms into expanded metal mesh? This versatile material, with its diamond-shaped openings, is essential in industries from construction to design. Choosing the right size is crucial for efficiency and safety. In this guide, you'll learn about expanded metal, its sizing importance, and applications across various sectors.

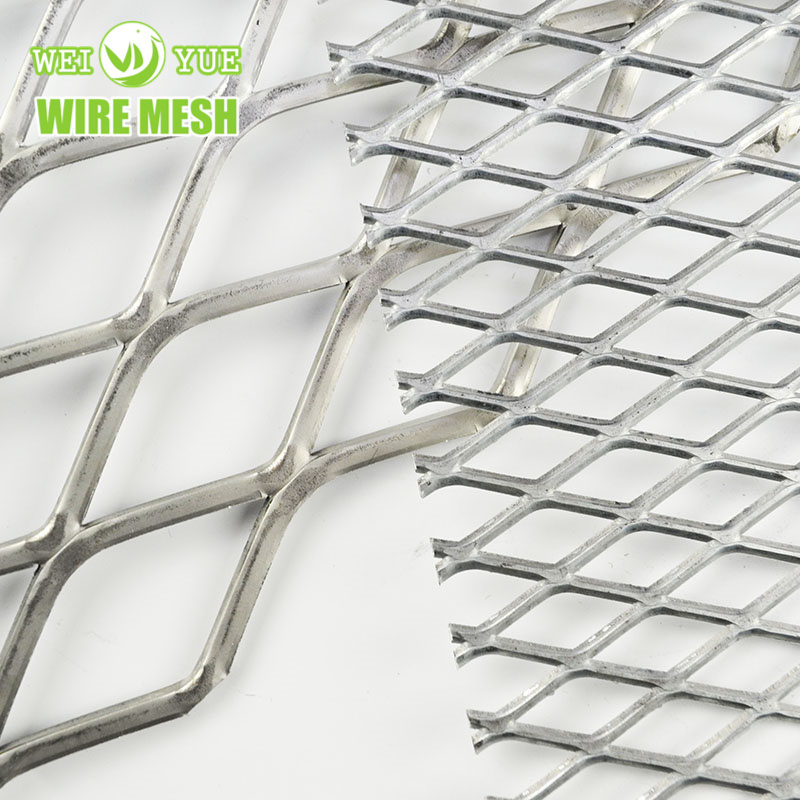

Expanded metal mesh is a type of metal sheet that has been cut and stretched to form a pattern of diamond-shaped openings. Instead of weaving or welding wires, the process creates a continuous sheet with openings, making it stronger and lighter than solid metal sheets. This mesh offers excellent strength-to-weight ratio, good ventilation, and drainage, making it ideal for many industrial and architectural applications.

Expanded metal mesh can be made from various metals, each offering unique properties:

● Carbon Steel: Strong and durable, suitable for heavy-duty uses. Often galvanized to resist rust.

● Stainless Steel: Corrosion-resistant and ideal for harsh environments. It combines strength with chemical resistance.

● Aluminum: Lightweight and corrosion-resistant but less strong than steel. Perfect for applications where weight is a concern.

● Galvanized Steel: Carbon steel coated with zinc for additional rust protection, commonly used outdoors.

Each metal type impacts the mesh's strength, weight, corrosion resistance, and cost, so choosing the right metal depends on the application.

The manufacturing of expanded metal mesh involves several key steps:

1. Slitting: A metal sheet is fed into a machine that makes precise slits in a staggered pattern.

2. Expanding: The sheet is then stretched, opening the slits into diamond shapes without cutting the metal into separate pieces.

3. Forming Strands: The stretching process creates angular strands that form the mesh's structure.

4. Finishing: Depending on the application, the mesh might be flattened, galvanized, or coated.

This process creates a strong, rigid mesh that maintains the integrity of the original metal sheet but with significantly reduced weight and increased surface area.

Note: The choice of metal type directly influences the expanded metal's performance and suitability for specific environments and tasks.

When selecting expanded metal mesh, understanding key measurements ensures you get the right fit and performance. Expanded metal comes mainly in two forms: raised and flattened mesh, each measured differently. Here’s a clear guide to the essential dimensions.

For raised mesh, these two terms describe the spacing of the diamond-shaped openings:

● Longway Pitch (LWP): The horizontal distance between points on the mesh, measured either from knuckle to knuckle or center to center of the diamonds. It reflects the tooling size used during manufacturing.

● Shortway Pitch (SWP): The vertical distance between points on the mesh, also measured knuckle to knuckle or center to center. It depends on how much the metal is stretched during production.

These pitches define the size of the diamond openings and influence how much light, air, or material can pass through.

● Strand Width (SWDT): This is the width of the metal strands forming the mesh. It’s important because wider strands mean stronger mesh but less open area.

● Strand Thickness (STK): The thickness of the original metal sheet before expansion. The expanding process does not change this thickness. For raised mesh, the thickness stays the same, but the mesh height (depth) can be 1 to 2 times the strand width.

Strand width and thickness together determine the mesh’s strength and durability.

For flattened mesh, measurements focus on the open spaces inside the diamond shapes:

● Longway Aperture (LWA): The horizontal distance measured inside the diamond from one internal point to the opposite internal point.

● Shortway Aperture (SWA): The vertical distance measured inside the diamond, similar to LWA but in the vertical direction.

Flattened mesh is pressed flat after expansion, so the metal thickness reduces by about 10-20%. This makes the mesh two-dimensional, and strand thickness reflects the original metal thickness less the flattening reduction.

Raised expanded metal mesh features strands that stand above the base plane, creating a three-dimensional texture. This angular, elevated form results from the initial slit and stretch manufacturing process. The mesh strands incline outward, giving the mesh depth and increased rigidity. Because of its raised profile, it offers excellent grip underfoot, making it ideal for applications like walkway ramps and stair treads. The open diamond patterns also allow air, light, and liquids to pass through easily, enhancing ventilation and drainage.

Raised mesh typically maintains the original metal thickness since the expanding process doesn’t alter thickness. However, the mesh height can be 1 to 2 times the strand width, adding structural strength. Its distinctive texture also adds aesthetic appeal for architectural uses such as decorative cladding and building facades.

Flattened expanded metal mesh undergoes an additional process where the raised mesh is pressed flat using heavy rollers. This results in a two-dimensional sheet with all strands lying in the same plane. Flattening reduces the metal thickness by about 10-20%, making the mesh thinner but smoother.

Flattened mesh features more uniform thickness and a sleek surface, which is better suited for applications requiring a clean finish or where snagging must be minimized. The diamond openings in flattened mesh are measured by Longway Aperture (LWA) and Shortway Aperture (SWA), focusing on the internal dimensions of the openings rather than pitch.

This type of mesh is commonly used for security partitions, machine guards, and air filters, where a smooth surface and consistent thickness are essential.

Raised mesh excels in environments where traction and drainage are critical. Common uses include:

● Walkway ramps and stair treads

● Exterior security fencing

● Decorative architectural panels

● Laths for plaster and render

Its three-dimensional form helps prevent slipping and allows debris or liquids to pass through easily.

Flattened mesh is favored when a flat surface or aesthetic uniformity is needed. Typical applications include:

● Security partitions and enclosures

● Machine guards and protective screens

● Conical air filters

● Decorative panels requiring smooth finishes

Its reduced thickness and flat profile also make it easier to weld or fabricate into assemblies requiring tight tolerances.

Selecting the right expanded metal mesh size depends on several important factors:

● Load Requirements: Consider the weight the mesh must support. Heavier loads need thicker strands and smaller openings for strength.

● Open Area Needs: More open space allows better airflow, drainage, or visibility. Smaller openings provide more security and strength but reduce openness.

● Environmental Conditions: Corrosive or harsh environments may require corrosion-resistant metals and specific mesh sizes that balance durability and performance.

● Application Purpose: Different uses demand different mesh sizes. For example, walkway flooring needs slip-resistant raised mesh with moderate openings, while decorative panels may favor larger openings and thinner strands.

The metal type directly affects the mesh size you can choose:

● Carbon Steel: Strong and durable, so you can use thinner strands and larger openings for the same load capacity compared to softer metals. It’s ideal for heavy-duty structural applications.

● Stainless Steel: Offers excellent corrosion resistance and good strength. Mesh size can be larger than carbon steel for similar strength but depends on grade and finish.

● Aluminum: Lightweight and corrosion-resistant but less strong. Requires thicker strands or smaller openings to carry the same load as steel. Best for applications where weight savings are critical.

● Galvanized Steel: Similar strength to carbon steel but with added rust protection, suitable for outdoor use. Mesh sizing follows carbon steel guidelines but consider coating thickness.

Here are some example mesh sizes and their typical uses (examples are illustrative; always verify with suppliers):

Metal Type | Strand Width (inches) | Strand Thickness (inches) | Approximate Open Area (%) | Typical Application |

Carbon Steel | 0.072 | 0.036 | 45 | Heavy-duty baskets, industrial flooring |

304 Stainless Steel | 0.080 | 0.037 | 70 | Food processing, chemical plants |

Aluminum | 0.094 | 0.051 | 70 | Lightweight enclosures, architectural |

For example, carbon steel with thinner strands but smaller openings can support more weight than aluminum mesh with thicker strands and larger openings. Stainless steel balances corrosion resistance and strength, making it suitable for many environments.

When ordering expanded metal mesh, specifying sheet size alone isn't enough. Orientation plays a key role. Expanded metal sheets feature diamond-shaped openings, and these diamonds can be oriented in two main ways: Longway Mesh (LWM) and Shortway Mesh (SWM).

● Longway Mesh (LWM): The longer dimension of the sheet runs parallel to the long axis of the diamond openings.

● Shortway Mesh (SWM): The shorter dimension of the sheet runs parallel to the long axis of the diamonds.

This orientation affects the mesh's mechanical properties and how it performs in your application.

For example, a 2440mm x 1220mm sheet ordered as LWM means the 2440mm length runs along the diamond’s long axis. The same sheet ordered as SWM means the 1220mm length runs along the diamond’s long axis. Both sheets have the same overall size but different diamond orientations.

Orientation impacts strength, grip, appearance, and usability.

● Mechanical Strength: The mesh is typically stronger along the long axis of the diamonds. For load-bearing applications, orienting the mesh so the long diamond axis aligns with the direction of the load improves strength.

● Grip and Safety: For raised mesh used as walkway ramps or stair treads, orienting diamonds left-to-right (across the foot) provides better grip and reduces slipping.

● Security: In fencing, mounting mesh with diamonds standing vertically (long axis up) narrows openings horizontally, deterring climbing and enhancing security.

● Appearance: Orientation affects how the mesh looks. For architectural panels, the diamond direction can create different visual patterns, influencing light and shadow play.

Errors in specifying sheet size and orientation can cause problems:

● Assuming Size Defines Orientation: Ordering a sheet by size alone without specifying orientation may lead to receiving mesh with diamonds oriented opposite your needs.

● Ignoring Application Needs: Not considering how orientation affects grip, strength, or security can reduce performance or safety.

● Mixing Raised and Flattened Orientation Terms: Raised and flattened mesh have different measurement terms, so specifying orientation without clarifying mesh type can cause confusion.

● Not Confirming with Manufacturer: Since manufacturers may have standard orientations, always confirm the orientation with your supplier before ordering.

Correctly specifying sheet size and orientation ensures your expanded metal performs as intended, looks right, and meets safety standards.

Expanded metal size charts help you pick the right mesh by showing key dimensions and weights. Understanding these terms is crucial:

● Mesh Size: Usually the distance from center to center of diamond openings. Larger mesh means bigger openings, letting more air or light through. Smaller mesh means stronger, more solid material.

● Sheet Width and Length: The overall size of the metal sheet. Standard sizes exist, but custom sizes are often available.

● Thickness (Gauge): Thickness of the original metal sheet before expansion. Lower gauge numbers mean thicker metal, which is stronger.

● Weight: Expressed as pounds per square foot or kilograms per square meter. Heavier mesh is generally stronger.

● Strand Diameter: The thickness of the metal strands forming the mesh. Larger diameters add strength.

Charts typically list these values so you can compare options and choose a mesh size that fits your needs.

Here are example size chart entries for steel and aluminum expanded metal. These examples illustrate typical ranges but always verify specs with your supplier.

Metal Type | Mesh Size (inches) | Sheet Size (inches) | Thickness (Gauge) | Weight (lbs/sq ft) | Strand Diameter (inches) |

Steel | 1 x 2 | 48 x 96 | 10 | 2.5 | 0.25 |

Steel | 1.5 x 3 | 48 x 96 | 12 | 1.8 | 0.18 |

Aluminum | 1/2 x 1 | 48 x 96 | 14 | 1.2 | 0.12 |

Aluminum | 1 x 2 | 48 x 96 | 12 | 1.6 | 0.16 |

These sizes demonstrate how steel generally weighs more and has thicker strands than aluminum for similar mesh openings.

Choosing the right expanded metal size depends on your application:

● Heavy-Duty Flooring or Security Fencing: Opt for smaller mesh sizes with thicker strands and heavier gauge steel for strength and durability.

● Decorative Panels or Lightweight Enclosures: Larger mesh sizes with thinner strands and aluminum or stainless steel provide good appearance and corrosion resistance without excess weight.

● Ventilation or Filtration: Mesh sizes that balance open area and strand thickness ensure airflow while maintaining structural integrity.

● Load-Bearing Capacity: Always confirm the mesh weight and strand diameter meet your load requirements.

Consider environmental factors like corrosion potential and exposure to chemicals when selecting metal type and thickness.

Expanded metal mesh is versatile, offering strength and lightweight properties. Accurate measurement and specification are crucial for optimal performance. Choosing the right mesh size involves considering load, open area, and environmental conditions. The expanded metal from Weiyue excels in various applications, providing strength, durability, and aesthetic appeal. With a wide range of options, Weiyue ensures that customers find the perfect solution for their needs, delivering exceptional value and quality.

A: Expanded Metal Mesh Stainless Steel Wire is a metal sheet cut and stretched to form diamond-shaped openings, combining strength with corrosion resistance, ideal for various applications.

A: Expanded Metal Mesh Stainless Steel Wire is used in industrial flooring, security fencing, and architectural panels due to its strength, ventilation, and aesthetic appeal.

A: Stainless Steel is chosen for Expanded Metal Mesh for its corrosion resistance and strength, making it suitable for harsh environments.

A: The cost of Expanded Metal Mesh Stainless Steel Wire is influenced by metal type, mesh size, and manufacturing processes like galvanization or coating.