Views: 310 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

When embarking on a new construction or design project, selecting the right materials is critical for achieving a balance of performance, aesthetics, and cost. One material that continues to stand out in a wide range of applications is expanded metal mesh. This unique material offers a blend of durability, flexibility, and versatility that makes it ideal for everything from architectural designs to industrial uses.

In this article, we will explore the key reasons why expanded metal mesh is an excellent choice for your next project. Whether you're looking for a strong, cost-effective material or one that offers impressive design possibilities, expanded metal mesh could be the ideal solution. We’ll dive into its core benefits, its practical applications across different industries, and how it can help you achieve both function and style in your next venture.

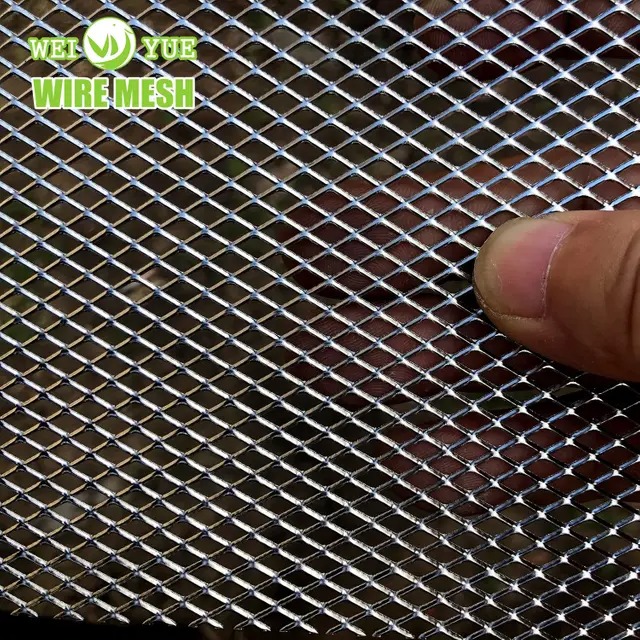

Expanded metal mesh is a sheet of metal that has been mechanically slit and stretched to form a mesh pattern. The result is a highly versatile material that combines the properties of solid metal with the lightweight and flexible nature of a grid or mesh structure. The unique expansion process increases the surface area of the material without adding extra weight, creating a mesh that is both durable and functional.

This type of metal mesh is made from a variety of metals, including stainless steel, aluminum, carbon steel, and copper. It can be manufactured in different thicknesses, sizes, and patterns to suit specific project needs. The expansion process allows the mesh to be tailored for different applications, whether that’s for added strength, airflow, visibility, or aesthetic appeal.

One of the most compelling reasons to choose expanded metal mesh for your next project is its remarkable durability and strength. Because it is created by expanding a solid metal sheet, the resulting mesh maintains the inherent strength of the original material. This makes expanded metal mesh ideal for applications where structural integrity is critical, such as in architectural facades, fencing, and industrial machinery.

Expanded metal mesh offers an excellent strength-to-weight ratio. The metal maintains its strength and structural integrity while reducing weight compared to solid sheets of metal. This makes it perfect for use in applications where strength is required without adding excess weight, such as in aerospace and automotive industries.

Certain types of expanded metal mesh, such as stainless steel or aluminum, are naturally resistant to corrosion. This resistance ensures that the mesh retains its strength and appearance even in harsh outdoor environments or industrial settings. The corrosion-resistant properties also extend the lifespan of the material, reducing maintenance costs over time.

Another significant advantage of expanded metal mesh is its versatility. Thanks to its customizable nature, expanded metal mesh can be used in a wide range of industries and applications. Whether you're working on a construction project, designing a decorative element, or manufacturing industrial products, this material can serve multiple functions.

In construction, expanded metal mesh is often used for facades, ceilings, and partition walls. Its ability to support loads while allowing light and air to pass through makes it ideal for modern architectural designs. Moreover, the mesh pattern can be customized to suit specific aesthetic needs, creating dynamic facades that enhance the overall design.

Expanded metal mesh is frequently used in industrial settings for safety barriers, grating, walkways, and filtration. The strength and flexibility of the mesh make it an excellent choice for harsh environments, including factories, warehouses, and power plants. It’s also widely used in manufacturing processes where filtration or separation is needed.

For designers and artists, expanded metal mesh offers endless possibilities for creating innovative structures, sculptures, and installations. The combination of lightness and durability makes it an ideal material for artistic creations that require both strength and visual impact.

When it comes to budgeting for a new project, cost-effectiveness is always a top priority. Expanded metal mesh offers a number of financial advantages that make it an attractive option compared to traditional solid metal sheets or other materials.

Because expanded metal mesh is created by stretching a single sheet of metal into a mesh pattern, there’s no need to use additional raw material to achieve the desired effect. This can significantly reduce material costs, especially when compared to solid sheets of metal, which require more material to cover the same surface area.

The lightweight nature of expanded metal mesh makes it easier and faster to handle and install compared to solid metal. This can reduce labor costs, especially in large-scale projects. The ease of installation also minimizes the need for specialized equipment or skilled labor, making it a cost-effective solution for a wide range of applications.

In today’s world, sustainability is more important than ever. Expanded metal mesh is a highly eco-friendly material, and its benefits go beyond just functional and aesthetic considerations. Choosing expanded metal mesh for your next project can contribute to a more sustainable approach to construction and manufacturing.

The expansion process of the mesh allows for the creation of a material that covers a larger area with less raw material. This reduces waste during production and minimizes energy consumption. The lightweight nature of expanded metal mesh also means that transportation costs and associated carbon emissions are lower compared to heavier materials.

Most types of expanded metal mesh, particularly those made from aluminum or stainless steel, are fully recyclable. This adds another layer of sustainability, as the material can be reused at the end of its life cycle, reducing the environmental impact of waste disposal.

One of the standout features of expanded metal mesh is its ease of installation. Whether it’s used for fencing, cladding, or as a structural element, expanded metal mesh can be installed quickly and efficiently, saving both time and money.

The lightweight nature of expanded metal mesh means it’s easier to transport and handle on-site. This can help reduce labor costs and the need for specialized machinery. The mesh panels can be cut to size and installed with minimal tools, which simplifies the installation process.

Expanded metal mesh is available in a wide range of patterns and sizes, allowing for a high degree of customization. Whether you need a small mesh for fine filtration or a large, open pattern for architectural facades, the material can be adapted to meet your specific needs without requiring significant modifications or additional processing.

While the functional benefits of expanded metal mesh are undeniable, its aesthetic potential should not be overlooked. With its geometric patterns and industrial look, expanded metal mesh can be used to create visually striking designs that complement modern architectural trends.

The open structure of expanded metal mesh can create an interesting interplay of light and shadow, adding a dynamic element to your design. The material can also be powder-coated in different colors, allowing for further customization to match the aesthetic of the project. This makes it an excellent choice for creating modern, innovative facades, partitions, and screens that are both functional and visually appealing.

Expanded metal mesh is an incredibly versatile, durable, and cost-effective material that offers numerous benefits for a wide range of applications. Whether you are working on a construction project, designing an industrial product, or looking for a sustainable material, expanded metal mesh should be high on your list of options. Its strength, versatility, aesthetic appeal, and ease of installation make it a smart choice for your next project.

Expanded metal mesh can be made from a variety of metals, including aluminum, stainless steel, mild steel, and copper. Each metal type offers different properties such as corrosion resistance, strength, and weight, making it suitable for different applications.

The primary difference between expanded metal mesh and welded wire mesh is in the manufacturing process. Expanded metal is formed from a single sheet of metal that is slit and stretched, whereas welded wire mesh is made by welding individual wires at each intersection. This makes expanded metal mesh stronger and more durable, while welded wire mesh is typically more flexible.

Yes, expanded metal mesh is often used for decorative applications. The material’s open pattern and structural properties allow designers to create visually interesting facades, partitions, and screens. It can also be powder-coated in various colors to suit different aesthetic preferences.

Yes, expanded metal mesh is relatively easy to maintain. If made from corrosion-resistant metals like stainless steel or aluminum, it requires minimal upkeep. Regular cleaning is usually enough to keep it in good condition, and its durability ensures it will last for many years.