What exactly is perforated metal, and why is it so widely used? From architectural facades to industrial filtration systems, this material plays a key role in numerous industries.

In this article, we’ll explore the features of perforated metal, its manufacturing process, and its diverse applications. You’ll learn how this versatile material is made and why it’s chosen for both functional and aesthetic purposes.

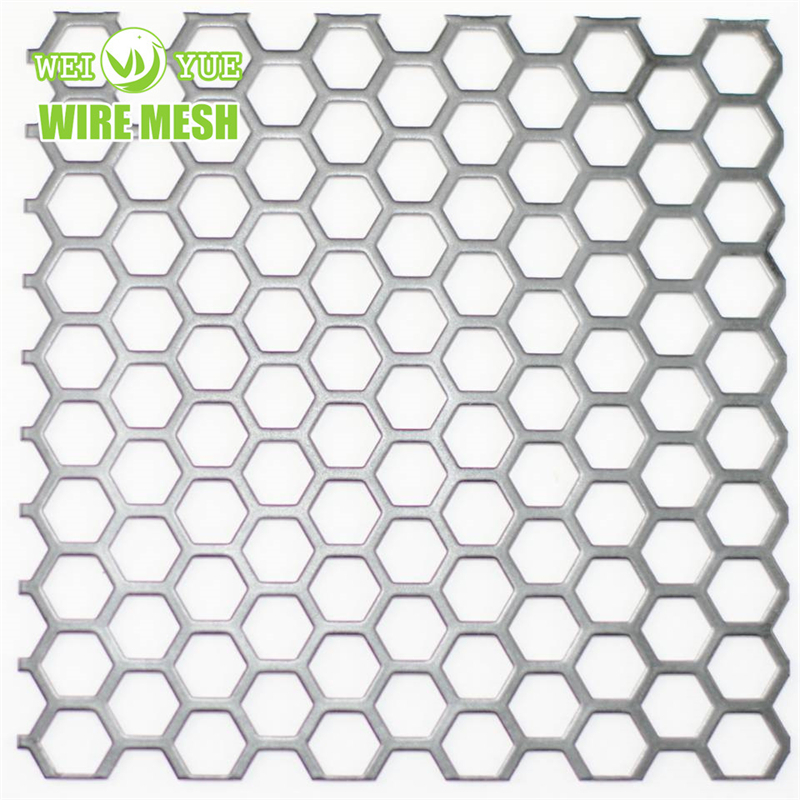

One of the main advantages of perforated metal is its ability to be tailored to meet specific design needs. Manufacturers can adjust the size, shape, and spacing of holes to create unique patterns that suit the application. Whether it's used for simple grids or complex geometric patterns, the versatility of perforated metal allows it to fit into a wide variety of design contexts.

This level of customization is especially important in architectural applications, where perforated metal is often used for building facades, sunshades, and decorative panels. By adjusting hole patterns, architects can control the amount of light and airflow that passes through, making it an excellent choice for energy-efficient buildings that also need to look aesthetically pleasing. Custom hole patterns can also be used for artistic elements, creating an interplay of light and shadow or adding a decorative touch to industrial spaces.

Furthermore, the flexibility in pattern design allows perforated metal to be used in both functional and decorative applications, such as creating attractive privacy screens, noise barriers, or filtration elements.

Despite the holes punched into it, perforated metal retains a high level of strength, making it a durable material for various applications. The material offers a great strength-to-weight ratio, meaning it provides the necessary structural support while minimizing overall weight. This is particularly advantageous in industries where weight plays a crucial role, such as architecture and automotive manufacturing.

For architectural projects, reducing weight is essential, as it lowers the overall load on a building's framework while still maintaining the material's integrity. Perforated metal panels are commonly used in facades, sunshades, and roofing, where they contribute to the overall structure without adding excess weight. This makes perforated metal an attractive solution for large-scale installations in both residential and commercial buildings.

In industrial settings, perforated metal is often used in machine guards, filtration systems, and other components where both strength and lightweight properties are essential for functionality. Its ability to withstand mechanical stress while remaining light enough for easy installation and handling is one of its key benefits.

In addition to its strength and customizable designs, perforated metal offers a variety of functional benefits. It is used extensively in applications that require the passage of air, light, water, or sound, making it ideal for industries ranging from ventilation and filtration to noise control and soundproofing. The perforations allow air or sound to pass through while maintaining structural integrity and protection.

For instance, perforated metal is commonly used in HVAC systems, where it allows airflow through ducts and vents without obstructing the movement of air. Similarly, in noise barrier applications, perforated metal provides a way to manage sound waves and reduce noise pollution, especially along highways or industrial areas.

In filtration applications, perforated metal is used in systems designed to separate materials based on size. It helps to filter liquids and gases by allowing smaller particles to pass through while blocking larger ones. This makes perforated metal an ideal material for air and water filtration, as well as for use in automotive and manufacturing industries.

Perforated metal has become an essential material in modern architecture, providing both functional and aesthetic value. In buildings, perforated metal can be used for facades, decorative screens, ceilings, and interior partitions. The material allows for natural light to filter into a building while also providing privacy and shading. Its design flexibility makes it a valuable tool for architects looking to incorporate light, air, and visual appeal into their designs.

For example, perforated metal is commonly used as sunshades or exterior cladding for buildings. The holes in the metal allow for light penetration while blocking excessive heat, contributing to the building’s energy efficiency. Additionally, the perforated pattern can enhance the visual appeal of a building by creating unique shadows and light patterns on the building's surfaces.

In interior design, perforated metal panels are used in ceilings, walls, and room dividers, where they provide functional benefits like acoustics control while also contributing to the overall design. The ability to create different hole patterns adds a layer of versatility, enabling designers to meet both performance and aesthetic goals.

Perforated metal plays a crucial role in a variety of industrial applications, where strength, durability, and the ability to filter or regulate airflow are important. Its versatility makes it a popular choice for manufacturing processes, automotive components, and machinery components.

In filtration, perforated metal is used to separate solid materials from liquids or gases. The consistent hole sizes allow for effective separation while maintaining the structural integrity of the material. Whether it’s used in air filters, water filters, or oil filters, perforated metal ensures that particles of a certain size are blocked, while the necessary fluid or gas passes through.

In industrial environments, perforated metal is also used for machine guards, grilles, and protective barriers. It protects machinery and personnel while allowing ventilation and visibility. This is especially useful in factories and plants, where safety is paramount, and airflow is crucial to the operation of machines.

Perforated metal is also commonly used in HVAC systems, where it functions as a filter or ventilation component that helps manage airflow while preventing the entry of debris or contaminants.

Perforated metal is created by using various methods such as punching, stamping, or laser cutting. These processes involve punching holes into metal sheets, which can be customized to specific designs or patterns. Punching is the most common technique, where a press is used to punch holes into the sheet, creating a uniform pattern.

Stamping involves pressing a die onto the metal to create more intricate or detailed designs. This method is used for decorative applications, where complex patterns are required. Laser cutting offers high precision and can create detailed custom patterns that would be difficult to achieve with traditional methods. Each method has its benefits, and the choice of process depends on the design complexity and the material used.

Perforated metal is highly customizable, allowing manufacturers to create products that meet specific design and performance requirements. The size and spacing of the holes can be adjusted to match the needs of the application, whether for aesthetic purposes or functional benefits such as filtration or ventilation.

For example, a high-security application might require smaller, denser holes to prevent unauthorized access, while a decorative feature might use larger holes to create a more open, airy design. Additionally, different hole shapes and patterns can be created, from simple round holes to intricate geometric patterns, giving designers the flexibility to achieve their vision.

Perforated metal can be made from a variety of materials, each chosen based on the specific application. The most common materials used include:

● Aluminum: Lightweight, corrosion-resistant, and easy to fabricate, aluminum is commonly used in architectural applications.

● Stainless Steel: Strong, durable, and resistant to corrosion, stainless steel is ideal for industrial applications or outdoor settings.

● Galvanized Steel: Coated with zinc to prevent rust, galvanized steel is commonly used for applications where corrosion resistance is essential.

Each of these materials offers unique benefits, and the choice depends on factors like environmental exposure, strength requirements, and design preferences.

Material | Properties | Best Used For |

Aluminum | Lightweight, corrosion-resistant | Security screens, facades, decorative panels |

Stainless Steel | Strong, corrosion-resistant | Outdoor applications, heavy-duty use |

Galvanized Steel | Corrosion-resistant due to zinc coating | Industrial filters, HVAC systems |

Perforated metal combines the strength of the base material with the ability to withstand harsh conditions. It is designed to endure mechanical stresses, environmental exposure, and wear over time. Whether used indoors or outdoors, perforated metal offers longevity and resistance to corrosion, particularly when materials like stainless steel or galvanized steel are used.

One of the biggest advantages of perforated metal is its design versatility. It can be used for functional purposes while also contributing to the aesthetic appeal of a space. With customizable patterns and finishes, it is a perfect fit for modern architecture and design, whether used for facades, partitions, or decorative elements.

Perforated metal is ideal for applications requiring airflow, light filtration, and sound control. It is used in noise barriers, machine guards, ventilation systems, and decorative pieces. The ability to adjust the size and pattern of perforations allows manufacturers to optimize the material’s performance for a wide range of needs.

Choosing the right material and pattern is critical to the performance of perforated metal. It is important to understand the environmental conditions and specific needs of your application. For example, materials like aluminum may be more suitable for aesthetic applications, while stainless steel is better for high-strength, outdoor uses.

While perforated metal is relatively low-maintenance, improper installation or failure to clean it regularly can lead to problems such as rust or poor performance. Be sure to follow manufacturer recommendations for installation and upkeep to extend the life of your perforated metal products.

Perforated metal is a versatile material with a wide range of applications in architecture, manufacturing, and design. Its ability to be customized in terms of size, shape, and pattern makes it ideal for both functional and decorative uses. From filtration systems to building facades, perforated metal provides strength, lightness, and durability.

At Hebei Weiyue Wire Mesh Products Co.,Ltd., we offer high-quality perforated metal products tailored to meet your specific needs. Our perforated metal solutions combine durability with aesthetic flexibility, ensuring the best results for your projects.

A: Perforated metal is a type of sheet metal that has been punched with holes or slots to create a pattern. It is used in various applications such as filtration, design, and ventilation, offering both functional and aesthetic benefits.

A: Perforated metal is made by punching or cutting holes into a metal sheet using methods like punch presses, stamping, or laser cutting. The process allows manufacturers to create customizable designs based on hole size and pattern.

A: Perforated metal is commonly used in architectural facades, filtration systems, noise barriers, and decorative designs. Its ability to allow light, air, and sound to pass through makes it versatile in many industries.

A: Perforated metal offers durability, strength, and design flexibility. It’s perfect for applications requiring both structural integrity and visual appeal, such as in architecture, manufacturing, and consumer goods.

A: The cost of perforated metal varies based on the material, hole pattern, and size. Generally, aluminum and stainless steel are more expensive, while galvanized steel offers a more affordable option for industrial applications.