Views: 0 Author: Site Editor Publish Time: 2025-06-24 Origin: Site

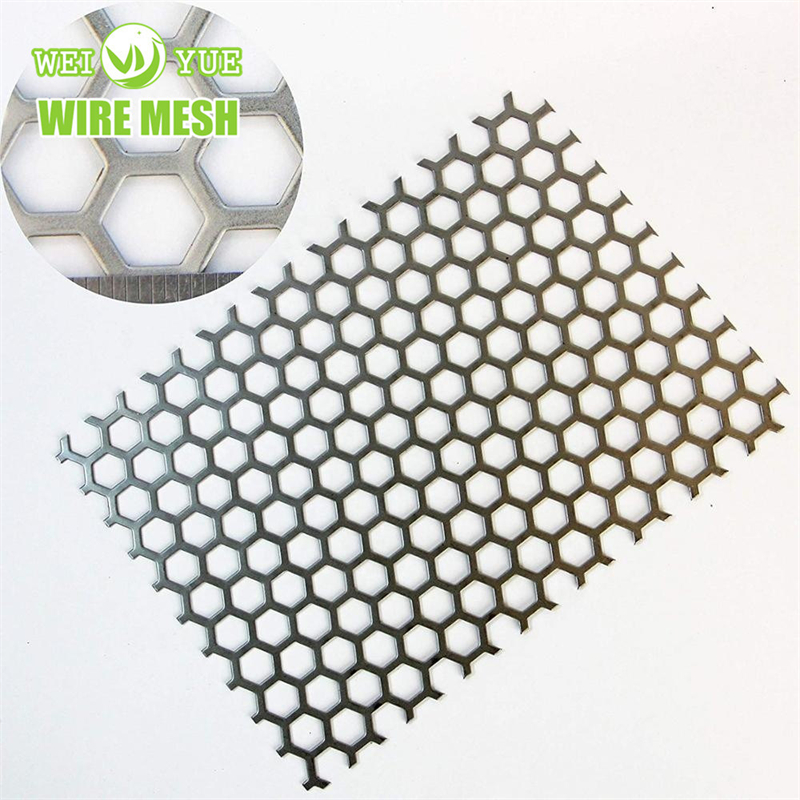

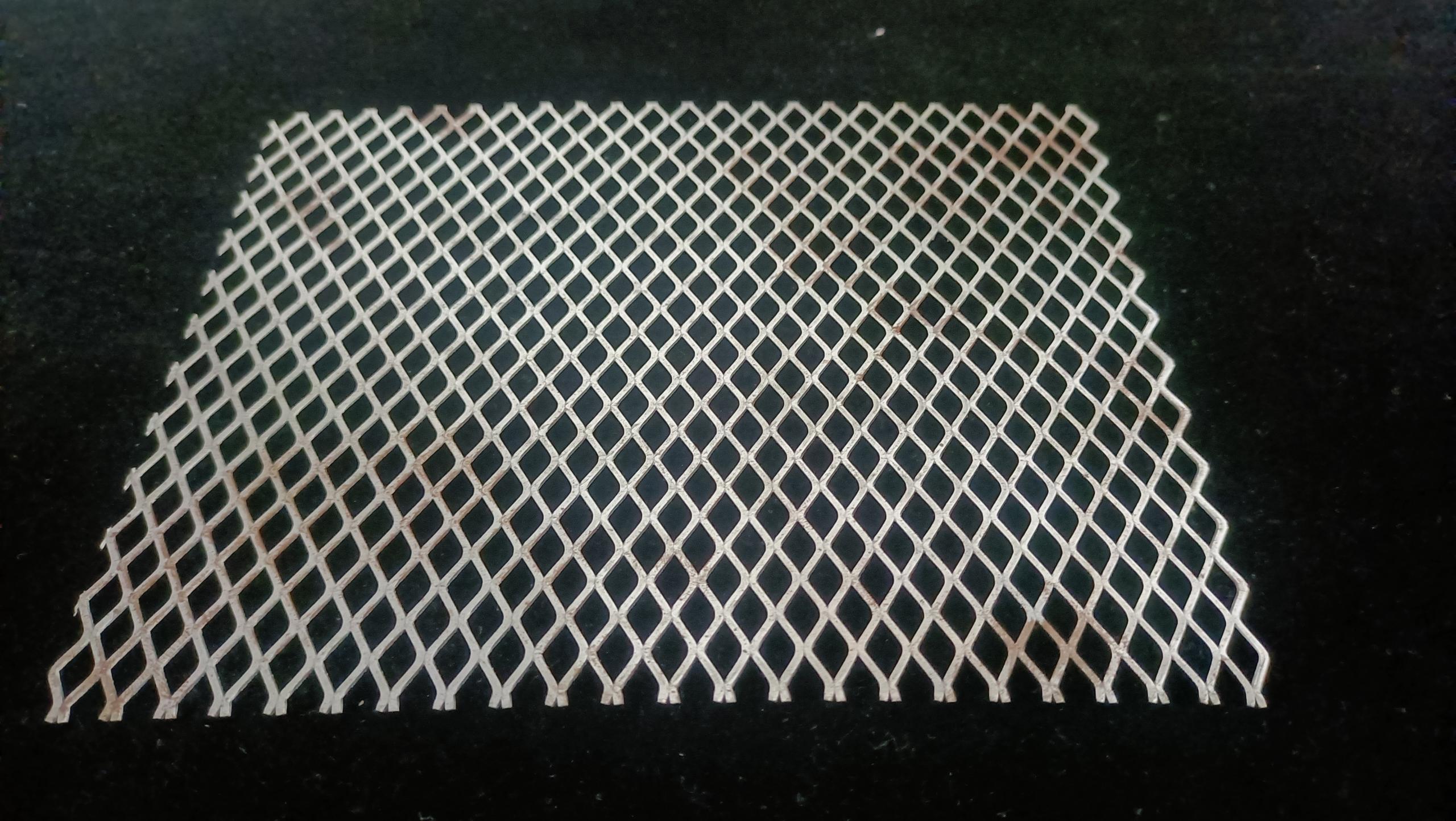

Stainless steel mesh is a versatile material that has found widespread use across a range of industries due to its unique combination of strength, durability, and resistance to corrosion. Composed of stainless steel wires woven together into a mesh structure, it is commonly employed in applications that require filtration, separation, reinforcement, and structural support. The mesh can be produced in various weave patterns, sizes, and grades, which makes it adaptable to different industrial requirements.

The applications of stainless steel mesh span across numerous sectors, including food processing, automotive, mining, construction, and especially industries that deal with chemicals and metals, such as the chemical fiber and electroplating industries. In these sectors, the need for durable, reliable, and high-performance materials is paramount, and stainless steel mesh has proven to be indispensable due to its exceptional properties.

Stainless steel mesh stands out in industrial applications due to its remarkable properties, which are essential in environments that subject materials to harsh conditions. Below are some key properties that make stainless steel mesh especially valuable for industries like chemical fiber and electroplating:

One of the most significant advantages of stainless steel mesh is its resistance to corrosion. Stainless steel contains a high amount of chromium, which forms a passive oxide layer on the surface of the material, protecting it from rust and oxidation. This corrosion resistance is critical in industries such as chemical fiber production and electroplating, where the material often comes into contact with corrosive chemicals, acids, and solvents. The ability of stainless steel mesh to maintain its integrity even in such aggressive environments makes it a preferred choice for filtration systems and other applications in these industries.

Stainless steel mesh can withstand high temperatures without losing its mechanical properties. This is essential in both chemical fiber and electroplating processes, where high-temperature environments are often required. In electroplating, for instance, the bath solution may be heated to ensure the metal ions are evenly deposited onto the workpiece. In the chemical fiber industry, heating processes are used to melt and extrude fibers. Stainless steel mesh, due to its excellent heat tolerance, can continue to perform efficiently without warping or degrading.

Stainless steel mesh is known for its high strength and durability, making it suitable for use in applications where mechanical stress is involved. Its structural integrity ensures that it can handle heavy-duty operations without bending or breaking, even when subjected to high pressure or abrasive conditions. The long lifespan of stainless steel mesh reduces the need for frequent replacements, making it a cost-effective option in demanding industrial settings.

In industries like chemical fiber production and electroplating, the materials used must not react with the chemicals or materials being processed. Stainless steel mesh’s non-reactive nature ensures that it does not interfere with the production process or affect the quality of the final product. This makes it an ideal choice for applications where purity and quality are critical.

The chemical fiber industry produces synthetic fibers from chemical substances, often through processes involving high temperatures, high pressures, and aggressive chemicals. Stainless steel mesh plays a crucial role in this industry, particularly in filtration and separation processes. Below are the primary ways stainless steel mesh is utilized in the chemical fiber sector:

During the chemical fiber production process, raw materials are often mixed with various chemicals to create fibers. The filtration process is essential for separating impurities, chemicals, and by-products from the desired material. Stainless steel mesh is used in filters because it allows for the efficient separation of fibers and chemicals while maintaining its integrity under harsh conditions. Its resistance to corrosion ensures that it can be used repeatedly without deteriorating.

Stainless steel mesh filters are commonly used to clean and purify the chemical solutions used in fiber production. They can be installed in filtration systems to trap particulate matter, ensuring that the final product is of the highest quality.

In addition to filtration, stainless steel mesh is also employed in separating materials during various stages of fiber production. For instance, in the extrusion process, stainless steel mesh is used to ensure that fibers are properly shaped and separated without interference from excess materials or contaminants. The mesh serves as a barrier to ensure that only the desired fiber passes through, while unwanted substances are filtered out. This enhances the efficiency of the production process and improves the quality of the final product.

Stainless steel mesh is also used as a reinforcing material in the machinery used for fiber production. Its durability and strength make it an excellent option for supporting components that are exposed to high pressure and heat during the manufacturing process. For example, it may be used in mesh belts or screens that help guide and shape the fibers as they are being produced.

Electroplating is the process of coating a metal object with a thin layer of another metal using an electrolytic solution. Stainless steel mesh is crucial in the electroplating industry due to its ability to withstand harsh chemicals, high temperatures, and electrochemical reactions. Below are some of the key applications of stainless steel mesh in electroplating:

In electroplating, the bath solutions used to deposit metal layers are often acidic or alkaline. These solutions need to be filtered regularly to remove impurities, prevent contamination, and ensure the consistency of the plating process. Stainless steel mesh is commonly used as a filter in these systems because it is chemically resistant and can handle the high acidity or alkalinity of electroplating baths.

By using stainless steel mesh filters, the electroplating process becomes more efficient, as the mesh ensures that the bath solutions remain clean and free of contaminants that could affect the quality of the metal coating. The mesh allows for continuous filtration, which helps maintain a consistent plating thickness and uniformity in the final product.

Stainless steel mesh is also used in the electroplating process to distribute chemicals evenly across the surface of the item being plated. The mesh is often used in the form of a mesh cathode or an anode basket, where it serves as a support structure for the chemicals. Its high strength ensures that it can hold up under the electrical currents and temperatures typically found in electroplating baths.

The electroplating process often involves continuous exposure to hot, corrosive solutions, as well as electrical currents. Stainless steel mesh is particularly well-suited to these conditions due to its excellent corrosion resistance and high strength, ensuring that it can withstand the demanding conditions of the electroplating environment without degrading.

Stainless steel mesh plays a crucial role in enhancing efficiency and maintaining high-quality standards across industries like chemical fiber and electroplating. With its exceptional properties—such as corrosion resistance, heat tolerance, strength, and long-term durability—it is ideally suited for environments where materials are exposed to harsh chemicals, high temperatures, and constant wear.

In the chemical fiber industry, stainless steel mesh is vital for filtration, separation, and reinforcement, ensuring that fibers are produced free from contaminants and with consistent quality. Similarly, in the electroplating industry, stainless steel mesh improves the filtration and distribution of chemicals, ensuring the uniformity and quality of electroplated surfaces.

As industries strive for greater operational efficiency and improved product quality, stainless steel mesh remains an indispensable material in both the chemical fiber and electroplating sectors. Its versatility and longevity make it a key player in driving success and innovation.

If you're looking to integrate high-quality stainless steel mesh into your operations, Hebei Weiyue Wire Mesh Products Co., Ltd. offers a range of reliable and durable solutions tailored to meet your needs. Visit their website or contact them directly to explore how their products can help enhance your industry’s performance and contribute to your success.