| Color: | |

|---|---|

| Size: | |

| Material: | |

| Availability: | |

WYRPMM

WEIYUE

7314500

HEBEI WEIYUE ROUND HOLE PERFORATIONS

Whether used for technical or decorative applications, round hole perforati are the most frequently used in perforated products.

Material | Mild Steel, Galvanized Steel, Aluminium, Stainless Steel, Corten Steel etc. |

Specifications | Stainless Steel, Hot Rolled Steel, Cold Rolled Steel, Aluminum plate |

Hole Pattern | Round hole, Square hole, Slotted hole, Decorative hole, Architectural hole etc. |

Thickness | 0.5mm-4mm (additional thickness are available on request) |

Hole size | 2mm-50mm (other hole sizes are also available) |

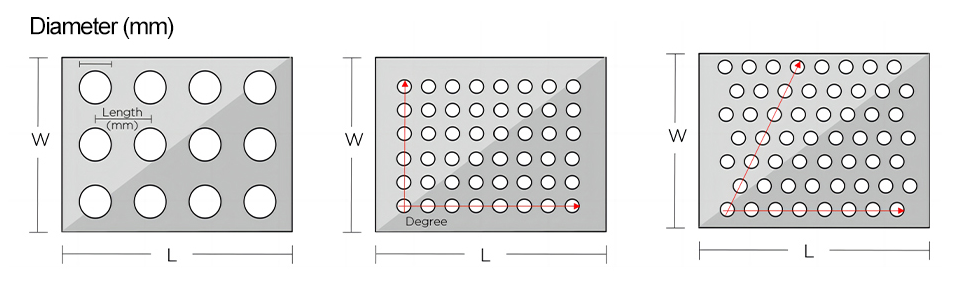

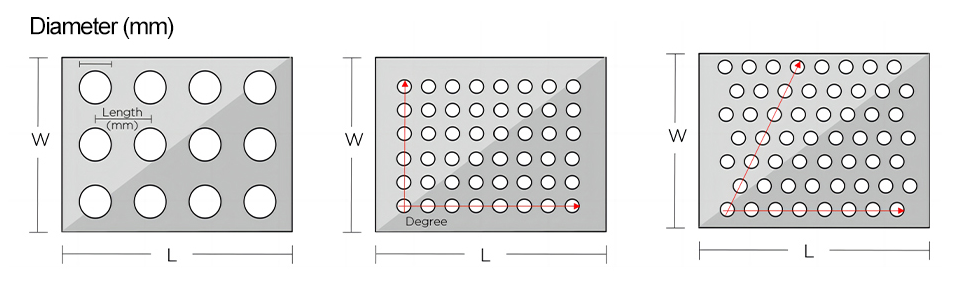

Arrangement Mode | straight row, staggered |

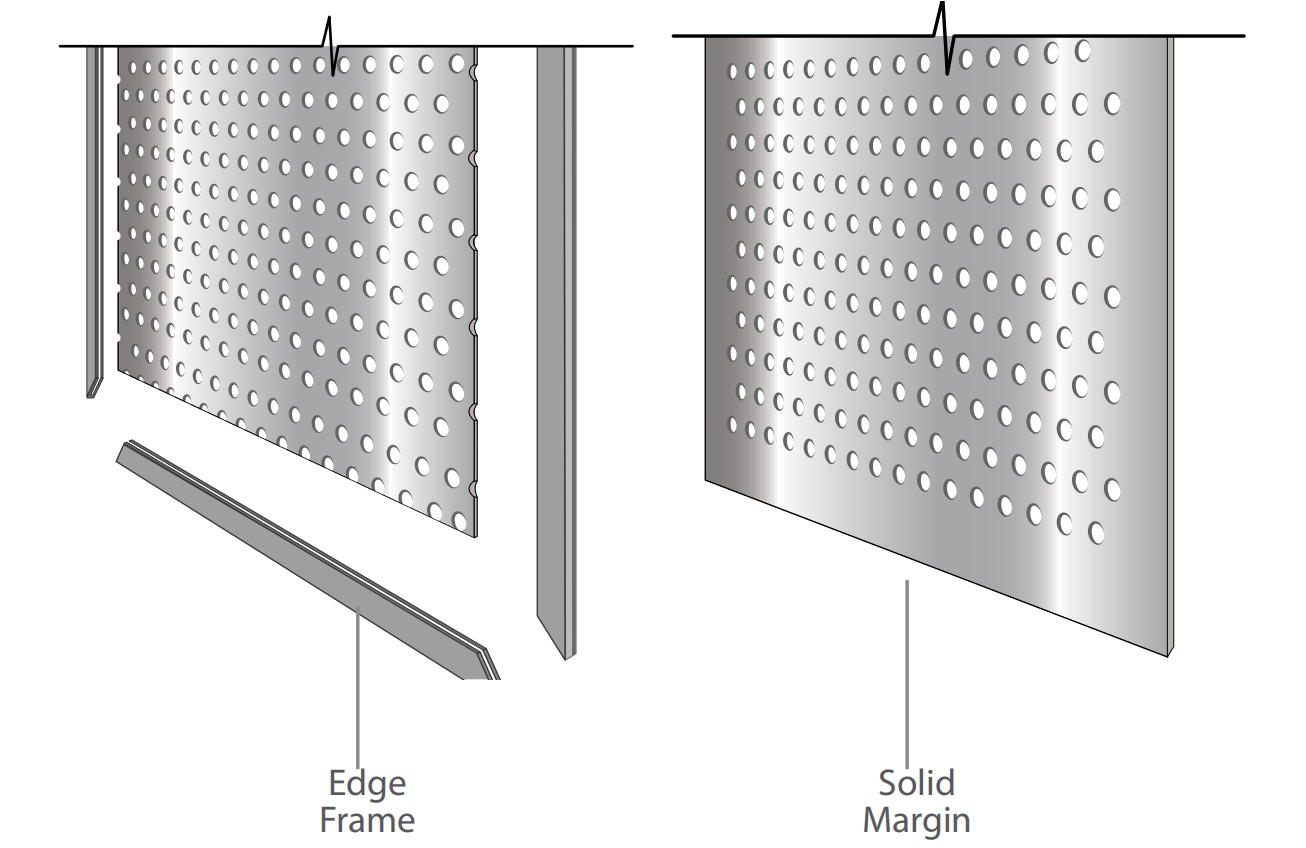

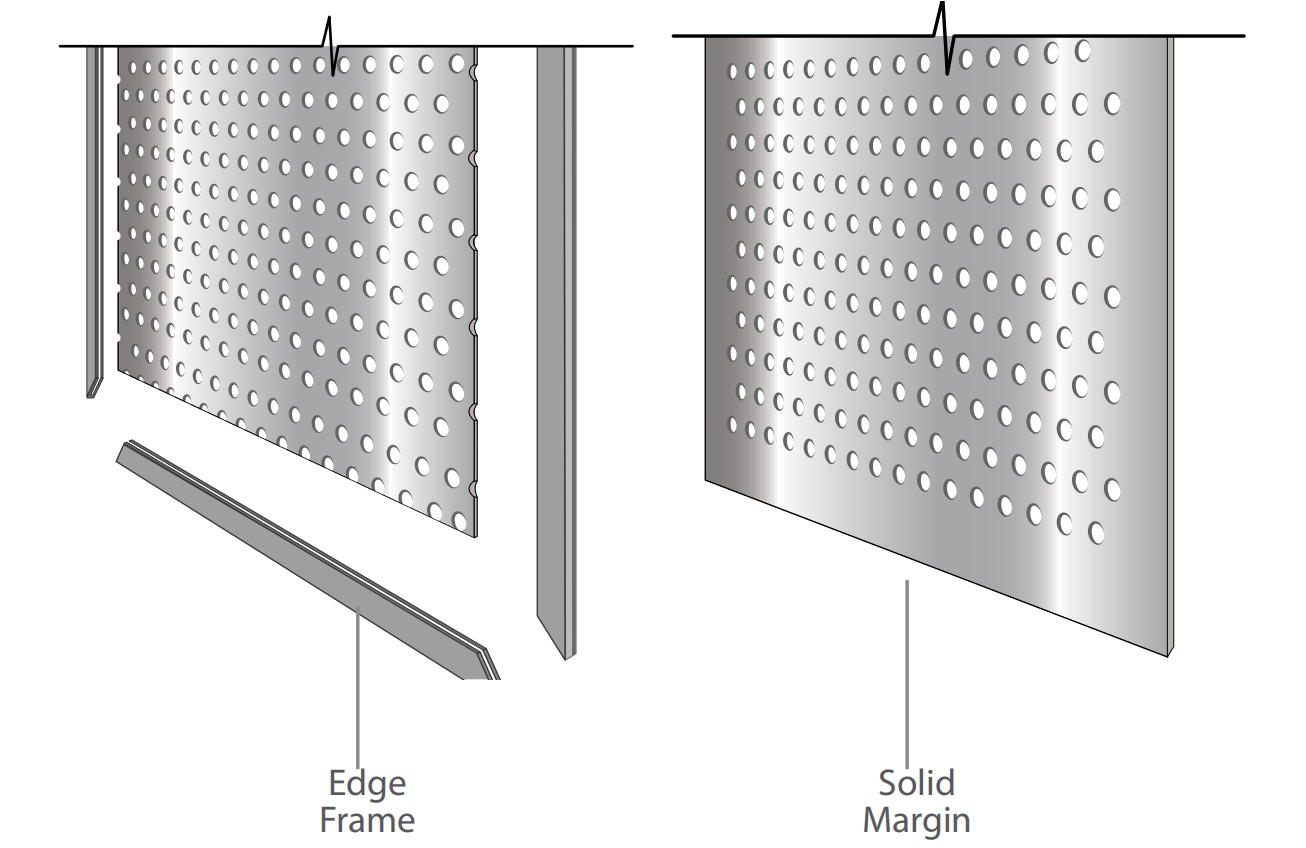

Margins | Finished end Pattern, Unfinished end Pattern, No Margin |

Width | 1m, 1.22m,1.5m, 2m etc. |

Length | 2m, 2.44m, 3m etc. |

Sheet size | 1m*2m, 1.22m*2.44m, 1.5m*3m(additional sizes are available on request) |

Application | security, sifting, machinery guards, enclosures, sign panels, noise reduction etc. |

Note | Perforations must be the same or larger in size than the material thickness. |

The Perforated Metal Sheet Mesh refers to the different shapes of holes punched in different materials to meet different needs.

1. Material:

Stainless steel, low carbon steel plate, galvanized PVC sheet, cold rolled coil, hot rolled plate, aluminum plate and so on.

2. Types:

Pattern punching net, forming punch net, special thickness punch net, special thin punch net, micro-hole punch net, line cutting perforation net.Laser perforation network and so on.

Round hole perforations provide the possibility of a large open area and strength and comes in triangular, diagonal, straight or staggered rows and also with decorative holes.

Hole Arrangement

Edge Opinions

Benefits

1. Perforated metals can be readily formed

2. Painted or powder coated

9. Many metals to choose from which saves additional finishing costs

Perforated metal panels can easily be made to site-specific requirements meaning customization is infinite and mixing different types of metals is ideal to enhance both new construction and remodeling.

Perforated metal panels are perfect for interior design. The result is an open area that provides an airy aesthetic that controls light and air movement, while elegantly blending industrial and other applications with their surroundings.

Perforated metal panels are perfect for room dividers to secure areas without blocking views

They provide a contemporary atmosphere and appearance

Thickness of metal can range widely from heavy structural applications to delicate interior designs

Different shapes and sizes available from simple circle patterns to ornate and intricate designs

Finish with a wide range of powder coat options to ensure protection from the elements, eliminate maintenance, and endure exposure without crazing or fading

HEBEI WEIYUE ROUND HOLE PERFORATIONS

Whether used for technical or decorative applications, round hole perforati are the most frequently used in perforated products.

Material | Mild Steel, Galvanized Steel, Aluminium, Stainless Steel, Corten Steel etc. |

Specifications | Stainless Steel, Hot Rolled Steel, Cold Rolled Steel, Aluminum plate |

Hole Pattern | Round hole, Square hole, Slotted hole, Decorative hole, Architectural hole etc. |

Thickness | 0.5mm-4mm (additional thickness are available on request) |

Hole size | 2mm-50mm (other hole sizes are also available) |

Arrangement Mode | straight row, staggered |

Margins | Finished end Pattern, Unfinished end Pattern, No Margin |

Width | 1m, 1.22m,1.5m, 2m etc. |

Length | 2m, 2.44m, 3m etc. |

Sheet size | 1m*2m, 1.22m*2.44m, 1.5m*3m(additional sizes are available on request) |

Application | security, sifting, machinery guards, enclosures, sign panels, noise reduction etc. |

Note | Perforations must be the same or larger in size than the material thickness. |

The Perforated Metal Sheet Mesh refers to the different shapes of holes punched in different materials to meet different needs.

1. Material:

Stainless steel, low carbon steel plate, galvanized PVC sheet, cold rolled coil, hot rolled plate, aluminum plate and so on.

2. Types:

Pattern punching net, forming punch net, special thickness punch net, special thin punch net, micro-hole punch net, line cutting perforation net.Laser perforation network and so on.

Round hole perforations provide the possibility of a large open area and strength and comes in triangular, diagonal, straight or staggered rows and also with decorative holes.

Hole Arrangement

Edge Opinions

Benefits

1. Perforated metals can be readily formed

2. Painted or powder coated

9. Many metals to choose from which saves additional finishing costs

Perforated metal panels can easily be made to site-specific requirements meaning customization is infinite and mixing different types of metals is ideal to enhance both new construction and remodeling.

Perforated metal panels are perfect for interior design. The result is an open area that provides an airy aesthetic that controls light and air movement, while elegantly blending industrial and other applications with their surroundings.

Perforated metal panels are perfect for room dividers to secure areas without blocking views

They provide a contemporary atmosphere and appearance

Thickness of metal can range widely from heavy structural applications to delicate interior designs

Different shapes and sizes available from simple circle patterns to ornate and intricate designs

Finish with a wide range of powder coat options to ensure protection from the elements, eliminate maintenance, and endure exposure without crazing or fading

Our perforated sheets with round hole perforations are used in many applications for example:

Sieves

for agriculture (sieves for sorting/grading of seeds and stones)

for the building industry

for the recycling industry (sorting of bulk materials)

Protection and ventilation sheets

Round holes are often used for acoustics and safety for the IT industry, as well as machinery construction for protection and ventilation panels.

Round holes offer a large ventilation opening with effective protection for the machine parts inside.

Facades

Square holes can be supplied with parallel rows, diagonal rows or staggered rows. In addition, square hole perforations allow a high open area for applications such as ventilation and guards.

Some examples of applications for perforated sheets with square hole perforation.

It can be used in road, railway, factory, building, and various decorative boards. And it is widely used in chemical machinery, pharmaceutical equipment, food and beverage machinery, cigarette machine, cutter, dry cleaners, ironing table, sound equipment, refrigeration equipment(central air conditioning), speakers, handicraft production, paper making, hydraulic accessories, filtration equipment and so on all walks of life.

Our perforated sheets with round hole perforations are used in many applications for example:

Sieves

for agriculture (sieves for sorting/grading of seeds and stones)

for the building industry

for the recycling industry (sorting of bulk materials)

Protection and ventilation sheets

Round holes are often used for acoustics and safety for the IT industry, as well as machinery construction for protection and ventilation panels.

Round holes offer a large ventilation opening with effective protection for the machine parts inside.

Facades

Square holes can be supplied with parallel rows, diagonal rows or staggered rows. In addition, square hole perforations allow a high open area for applications such as ventilation and guards.

Some examples of applications for perforated sheets with square hole perforation.

It can be used in road, railway, factory, building, and various decorative boards. And it is widely used in chemical machinery, pharmaceutical equipment, food and beverage machinery, cigarette machine, cutter, dry cleaners, ironing table, sound equipment, refrigeration equipment(central air conditioning), speakers, handicraft production, paper making, hydraulic accessories, filtration equipment and so on all walks of life.