Views: 0 Author: Site Editor Publish Time: 2026-02-21 Origin: Site

Stainless steel mesh is essential for various applications, but choosing the right one can be overwhelming. With so many types and grades, how do you know which one best fits your needs?

In this article, we’ll guide you through the process of selecting the right stainless steel mesh. You’ll learn how to assess your specific requirements and make an informed choice for optimal performance and durability.

When choosing stainless steel mesh for filtration or sieving, the mesh size and wire diameter are two critical factors. The mesh size determines the size of particles that can pass through, making it essential to match the mesh size to the specific requirements of the filtration task.

For example, a mesh with a higher mesh count (smaller openings) is ideal for filtering fine particles like dust or bacteria, while a coarser mesh is used for sieving bulkier materials like sand, gravel, or coarse powders. It’s also important to consider the wire diameter—thicker wires are suitable for heavier filtration tasks, while thinner wires are ideal for finer, more precise filtration applications.

Stainless steel mesh should be durable enough to withstand high flow rates or pressures depending on the application. Fine woven meshes are perfect for delicate filtration, while heavier, welded meshes provide strength for industrial sieving applications.

Filtration Type | Mesh Count | Wire Diameter | Application Example |

Fine Filtration | 150–400 | 0.05–0.13 mm | Pharmaceutical Filtration |

General Filtration | 40–100 | 0.15–0.28 mm | Water Treatment |

Coarse Sieving | 1–20 | 0.3–0.5 mm | Sand or Gravel Sieving |

Stainless steel mesh is widely used in reinforcement applications for construction, as well as in fencing and enclosures. Welded and crimped mesh are the most commonly used options for these purposes. Welded mesh provides enhanced structural integrity, making it ideal for concrete reinforcement, fences, and animal enclosures.

Stainless steel mesh used for fences must withstand harsh weather conditions while providing security. For this reason, it's important to choose a mesh with smaller openings and thicker wires for enhanced durability. Similarly, when reinforcing concrete structures, mesh strength plays a significant role in ensuring that the reinforcement holds up under pressure.

Mesh for stainless steel fences can also vary in terms of aesthetic appeal. The material allows for both functional and decorative designs, creating barriers that look as good as they perform.

In screening and ventilation applications, stainless steel mesh is commonly used in windows, doors, and HVAC systems to allow airflow while blocking larger particles, insects, or debris from entering. The mesh’s primary function is to allow airflow while blocking larger particles, insects, or debris from entering.

In environments like homes, offices, or industrial plants, stainless steel mesh ensures that ventilation systems operate efficiently without compromising air quality. When choosing the right mesh, it's important to consider the airflow requirements and the need for protection from external elements.

Stainless steel mesh also plays a significant role in architecture, providing both functional and aesthetic benefits. Expanded and woven mesh are often used in building facades, partitions, and decorative panels. It adds aesthetic value while also serving practical purposes like providing sunshading and privacy.

When selecting mesh for decorative purposes, the design flexibility of stainless steel mesh is a significant advantage. Architects can use it to create unique patterns or incorporate it into walls, facades, and ceilings, enhancing both the functionality and visual appeal of a space.

Grade 304 stainless steel is the most widely used stainless steel grade due to its excellent balance of strength, corrosion resistance, and cost-effectiveness. It is ideal for general-purpose applications, such as in kitchen appliances, decorative pieces, and industrial uses where corrosion resistance is required, but not necessarily in extreme conditions.

This grade is commonly used in stainless steel mesh for applications exposed to mild chemicals, food processing, and environments where moisture is present but extreme corrosion isn’t a concern. Grade 304 provides adequate protection against rust, making it a go-to material in many industries.

When it comes to environments exposed to saltwater, harsh chemicals, or extreme conditions, Grade 316 stainless steel is the ideal choice. This grade offers superior corrosion resistance, particularly to chlorides, which makes it perfect for use in marine environments, chemical processing, and food industries.

Grade 316 stainless steel mesh is often used in outdoor applications exposed to saltwater, such as in coastal regions, or in industries where chemicals can cause rust and degradation. Its exceptional corrosion resistance ensures that the mesh remains intact even in the harshest conditions.

If your application doesn’t involve exposure to moisture or harsh chemicals, Grade 430 stainless steel may be a cost-effective solution. It offers moderate corrosion resistance and is commonly used in indoor applications, such as automotive parts, kitchen appliances, and other decorative features.

Although Grade 430 is more affordable than Grade 304 or 316, its corrosion resistance is limited. It is most suitable for applications in dry environments that don’t require the extreme durability found in marine or chemical industries.

Woven stainless steel mesh is the most commonly used type, known for its flexibility and versatility. It is widely used in filtration, sieving, and screening applications. The weave pattern—whether plain, twill, or Dutch—affects the strength and filtration capability of the mesh.

For example, plain weave is the most common and is suitable for a wide range of applications requiring both strength and fine filtration. Twill weave is often used for higher strength and durability in applications requiring fine filtration at lower flow rates.

Welded stainless steel mesh is preferred for applications that require high strength and rigidity, such as in fencing, animal enclosures, and structural reinforcement. This type of mesh is made by welding the wire intersections, which gives it superior durability and resistance to physical stress.

Welded mesh is ideal for heavy-duty applications and can withstand high loads, making it perfect for use in industrial settings, security barriers, and even architectural elements that require high strength.

Expanded mesh is made by slitting and stretching a metal sheet, creating a mesh with larger openings. This type of mesh is commonly used in applications where strength and airflow are critical, such as walkways, grilles, and decorative elements. It’s also widely used in the manufacturing of safety barriers and architectural screens.

Unlike woven or welded mesh, expanded mesh does not require weaving or welding, making it more cost-effective and faster to produce, especially in large quantities.

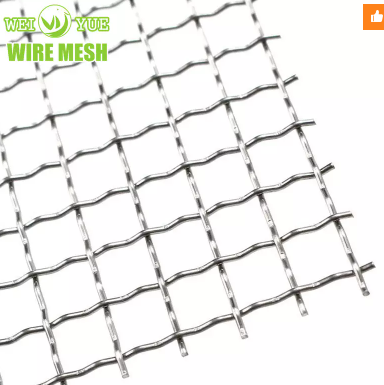

Crimped mesh is used in applications that require heavy-duty performance, such as screens and grill bars. It provides extra rigidity and strength, making it suitable for demanding environments. Perforated stainless steel mesh, on the other hand, is ideal for ventilation, acoustic control, and design elements, such as in facades or noise barriers.

Crimped and perforated meshes can be customized in terms of hole sizes and patterns, allowing for specific applications, such as controlling airflow or reducing noise levels.

The mesh count refers to the number of openings per inch in the mesh. A higher mesh count indicates a finer mesh, suitable for precise filtration tasks such as sieving powders or filtering small particles in liquids. Lower mesh counts are typically used for more open meshes required for structural or general applications, like fencing.

Wire diameter directly impacts the strength and durability of the stainless steel mesh. Thicker wires offer greater strength and are ideal for heavy-duty applications, such as fencing or structural reinforcement. Thinner wires are used for applications where filtration or aesthetic qualities are the primary concern.

Application | Mesh Count | Wire Diameter | Opening Size |

Insect Screens | 18–30 | 0.28–0.33 mm | 1.0–0.5 mm |

General Filtration | 40–100 | 0.15–0.28 mm | 0.37–0.15 mm |

Fine Filtration | 150–400 | 0.05–0.13 mm | 0.10–0.04 mm |

Structural Fencing | 1–4 openings | 3–6 mm | 6–25 mm |

When stainless steel mesh is exposed to chemicals or saltwater, selecting the right grade is critical. Grade 316 provides excellent resistance to chlorides, making it ideal for use in marine environments or industries that require protection from harsh chemicals.

If the stainless steel mesh will be exposed to high temperatures or abrasive conditions, it’s essential to choose materials that can withstand extreme heat. Grade 316 or Grade 310 stainless steel mesh are suitable for such conditions, offering high heat resistance.

For applications in humid or corrosive environments, Grade 316 is the go-to option, as it offers enhanced corrosion resistance. In highly humid environments, selecting the right stainless steel mesh ensures long-term durability and performance.

The cost of stainless steel mesh varies depending on the material grade, mesh type, and wire diameter. While Grade 316 offers superior corrosion resistance, it is more expensive than Grade 304 or Grade 430. It’s important to balance cost with performance based on your project’s needs.

Standard stainless steel mesh is more affordable and readily available, while custom mesh options are often more expensive and have longer lead times. Custom meshes provide unique specifications that may be required for specific applications but should be considered in terms of budget and project deadlines.

Choosing the right stainless steel mesh is essential for achieving the desired performance and longevity in any application. By carefully considering the mesh type, material grade, wire diameter, and environmental factors, you can select the perfect mesh for your project. Whether for filtration, reinforcement, or decorative purposes, the right mesh ensures both durability and efficiency.

At Hebei Weiyue Wire Mesh Products Co.,Ltd., we offer a wide range of high-quality stainless steel mesh solutions designed to meet diverse industrial and architectural needs. Our products combine exceptional strength, corrosion resistance, and design flexibility, making them an ideal choice for projects requiring both function and style.

A: Stainless steel mesh is a woven or welded material made from stainless steel wires. It is used in a variety of applications, including filtration, reinforcement, and decoration, due to its durability and corrosion resistance.

A: To choose the right stainless steel mesh for filtration, consider the mesh count (the number of openings per inch) and the wire diameter. Finer meshes are used for precise filtration, while coarser ones are used for sieving larger particles.

A: Grade 316 stainless steel is ideal for marine environments because it has superior corrosion resistance, especially to saltwater and chlorides. This makes it highly durable in harsh, salt-exposed conditions.

A: The cost of stainless steel mesh depends on factors such as the material grade, mesh type, wire diameter, and size. Higher-grade meshes like Grade 316 are more expensive but offer better resistance to harsh environments.

A: Yes, stainless steel mesh is commonly used for decorative purposes in architecture and design. Expanded mesh or woven patterns can create visually appealing facades, screens, and partitions while maintaining functional properties like airflow and privacy.